STANDING SEAM | EXPOSED FASTENER | METAL SHINGLES

UPGRADE TO A METAL ROOF

A metal roof is a stunning and long-lasting alternative to asphalt. This roofing material has been used for centuries because it is durable, waterproof, and beautiful. When properly maintained, certain metal roof materials can last for centuries. Hildesheim Cathedral in Germany has an original copper roof that was installed in 1280 AD, and Kronborg Castle has copper roofs that were installed in 1585 AD. This resilience gives metal roofs a lasting value that adds curb appeal and often a higher resale price to homes.

Generally the thinnest and lightest of roofing materials, metal tends to shed snow and rain quickly. It also offers tremendous life cycle savings. Newer technical improvements make the latest metal roof materials better than ever for sloped roofs. Finishes and waterproof fasteners have been created to make metal roofs less expensive, easier to install and less maintenance intensive.

Types of Metal Roofing

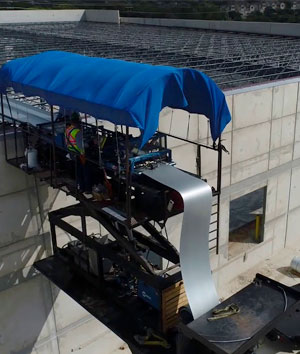

Antebellum Roofworks manufactures and installs their own metal roofing products to ensure the highest quality. We have all types of metal roofing materials available, from copper to stainless steel to aluminum and alloys. There are three general choices of metal roofing types:

- Standing Seam — A traditional favorite: Standing seam is an increasingly popular metal roof choice that evokes a country charm or industrial-chic feel. It is identified by its parallel raised seam lines running from the apex of the roof to the eaves. We can install either Mechanically Seamed, Snap Lock or Nail Strip standing seam roof systems.

- Exposed Fastener Panels — An economical choice: Exposed fastener panels have a similar look to standing seam roofs except the ridges are less prominent and they are intermittently spaced based on the panel placement. You are also able to see the fasteners upon a closer look, but they are the same color as the roofing material and do not interrupt its beauty. We offer a full line of exposed fastener panels that are relatively inexpensive and come in a variety of styles and colors. Please note that not all homes and structures are

designed for this metal roofing choice. Roof pitch, size and details such as valleys and walls create design limitations that affect weatherproofing integrity. Exposed fastener panels are designed for agricultural applications. - Metal Shingles — A beautiful alternative: Metal shingles have a design very similar to the familiar asphalt shingles. Like regular shingles, they are quick to install, easy to repair and can conform to almost any roof shape with ease. They can come in a wide variety of cut shapes, finishes and colors. We supply and install a full line of the best metal shingle products with a full range of styles and choices.